|

| Products » Drilling » Countersinks |

|

|

| Countersinks |

|

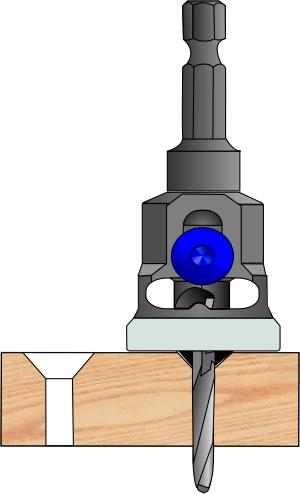

A countersink is a conical hole cut into a manufactured object such as wood, or the cutter used to cut such a hole. A common usage is to allow the head of a countersunk bolt or screw, when placed in the hole, to sit flush with or below the surface of the surrounding material. (By comparison, a counterbore makes a flat-bottomed hole that might be used with a hex-headed cap screw). Dimar offers a wide selection of Carbide Tipped and HSS Countersinks to accommodate screws from size 3 to size 16.

|

|

|

|

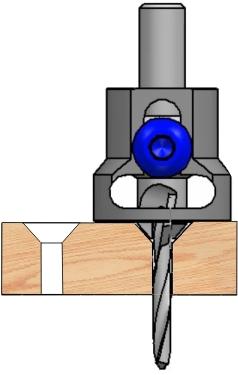

Dimar’s Nova Industrial Carbide Tipped Adjustable Countersink –Tool # 202-CS:

Why purchase twenty different size countersinks when one tool does it all?

This innovative tool developed by Dimar’s talented engineering department is ONE countersink that fits ALL drill diameters from 1/8” (3.0mm) to 9/32” (7.2mm). The countersink consists of two Carbide cutting teeth. The double cutting teeth perfectly grip your own drill by means of two screws, allowing for easy adjustments of both the depth and diameter of the countersink. Drilling & Countersinking is now done in one operation, giving you full control over the depth and the diameter desired. This countersink will accommodate any drill, be it Metric or Inch, and it will enable you to countersink for any screw from size 3 to 16.

|

|

|

|

Prior to using wood screws, it is advisable to drill a “Pilot Hole”. In case of an assembly of Drill and Countersink, one needs to determine the proper diameter of a drill to achieve the perfect hole size to accept a specific screw, or vice versa: the correct screw size (Gauge) for a given drill diameter. A “Pilot hole” is a hole drilled into a wood surface prior to installing a screw. Pilot holes help to:

♦ Prevent wood from splitting from large screws or when near the end or edge of the board.

♦ Improve positioning accuracy by providing a guide path for the screw to follow. This is very handy when installation of screws is done “Freehand”.

♦ Makes driving the screws into the wood easier.

Many parameters influence matching the drill diameter to the screw size (Gauge). Type of wood, moisture content, working conditions and angle of operation have great impact on this task. The following chart will give you a quick guideline.

| Screw Size(Gauge) |

Hard Wood |

Soft Wood |

| Tapered Drill |

Straight Drill |

Tapered Drill |

Straight Drill |

| 2 |

3/32 |

1/16 |

5/64 |

1/16 |

| 3 |

7/64 |

5/64 |

3/32 |

1/16 |

| 4 |

7/64 |

5/64 |

3/32 |

1/16 |

| 5 |

1/8 |

3/32 |

7/64 |

5/64 |

| 6 |

9/64 |

7/64 |

1/8 |

3/32 |

| 7 |

5/32 |

7/64 |

9/64 |

3/32 |

| 8 |

11/64 |

1/8 |

5/32 |

7/64 |

| 9 |

3/16 |

9/64 |

11/64 |

1/8 |

| 10 |

13/64 |

9/64 |

3/16 |

1/8 |

| 12 |

7/32 |

5/32 |

13/64 |

9/64 |

| 14 |

1/4 |

11/64 |

15/64 |

5/32 |

| 16 |

9/32 |

3/16 |

17/64 |

11/64 |

| 18 |

5/16 |

7/32 |

19/64 |

13/64 |

| 20 |

21/64 |

15/64 |

5/16 |

7/32 |

| 24 |

3/8 |

17/64 |

3/8 |

1/4 |

|

|

|

|

|